Metal Roofing Problems

This comprehensive guide gives an overview of metal roof problems, focusing on potential issues linked to installation, maintenance, and weather-related concerns. From my field experience with metal roofing systems, proper understanding of these challenges is what truly ends up equipping property owners with the right knowledge to stay prepared and address issues before they arise. Although metal roofs are a popular roofing material, no product is perfect, and even well-cared for systems can experience problems depending on variables affecting performance and factors beyond human control.

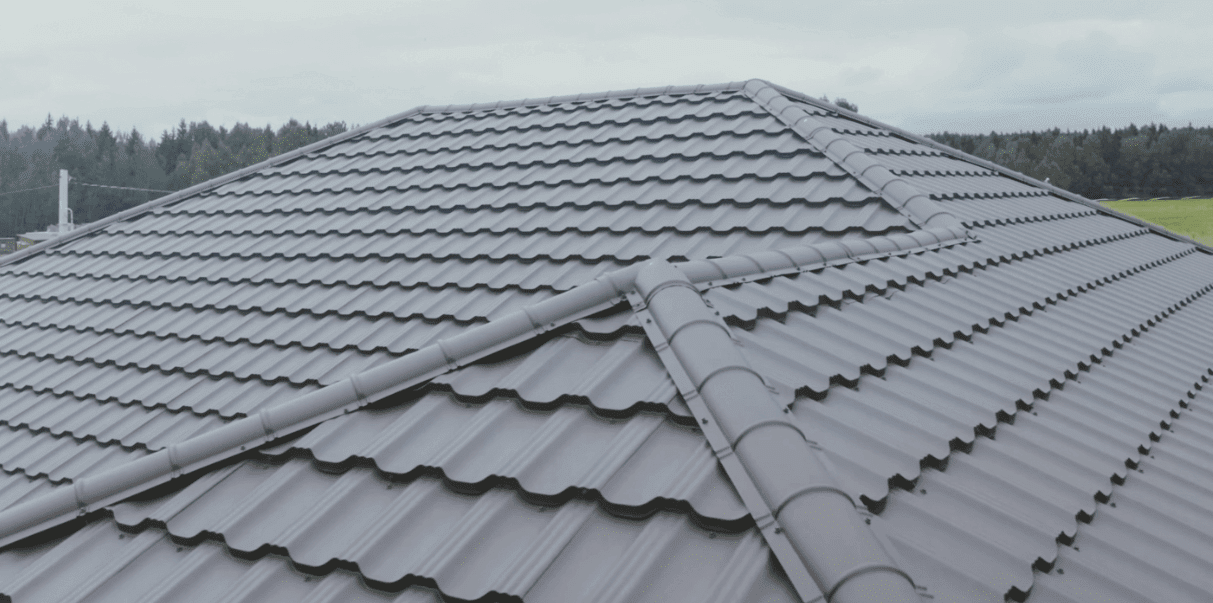

Built from high-quality metals like steel, aluminum, and copper, a metal roof is crafted and designed to withstand the harshest weather conditions, including heavy rainfall, strong winds, and intense heat, offering reliable protection from natural elements. Known for exceptional durability, longevity, and versatility, these metal roofs serve residential, commercial, and industrial buildings, often outlasting traditional roofing materials such as asphalt shingles and concrete tiles. Their fire-resistant nature helps in reducing risk of damage, destruction, and fires, while the inherent strength of metal roofing allows it to endure for decades, even when problems over time do occur.

Despite minimal maintenance, saving time and money, and being environmentally friendly, with materials that can be recycled at the end of their lifespan and even infinitely recycled without compromising qualities, some potential pitfalls still easily happen. Issues may encounter building owners across residential homes and commercial buildings, whether related to metal roof coating, architectural roof coating, or a metal firehouse roof structure. While there are fewer long-term problems compared to alternatives, it still depends on how the metal, roofs, and overall structure are handled. This article aims to educate consumers by outlining the top seven common problems, practical methods to remedy, avoid, and mitigate them, along with important considerations to bypass problems, ensuring a winning combination of durability, functionality, visual appeal, aesthetic appeal, sleek appearance, and flexible color options remains intact.

10 Common Metal Roof Problems

#1: Oil Canning

In metal roofing projects, oil canning is commonly defined by the Metal Construction Association as visible waviness across flat areas of metal roofing and metal wall panels, where, in technical terms, elastic buckling and stress wrinkling occur in any type of metal panel such as steel, aluminum, zinc, or copper. From hands-on site work, this issue is an inherent characteristic of nearly all metal roofs and walls, especially in a standing seam metal system when the metal becomes over-stressed, unable to hold a flat form, begins to give in, and create visible waves. It remains one of the hottest topics because it is difficult to define and measure, even though a clear number of reasons explain why it appears.

Most causes start with over-production, where extreme pressure during coiling creates frequent stress, followed by coil slitting, cutting, and rollforming panels. Problems also occur due to inadequate space for thermal expanding and contracting of panels, or changes in the structure’s original form that add tension and moves panels out of place. I have seen improper usage, handling, and storage by installers, or a panel not installed according to specified dimensions of the structure, generate oil canning when contractors fail to follow industry-standard manufacturer installation details. Practical ways to reduce the likelihood include purchasing thicker metal, using a rib roller profile to break up flat space, choosing a low-gloss or matte finish to reduce reflectivity and decrease visibility, buying tension-leveled or stretched metal where the coil is stretched beyond its original state, and properly install the roof on a flat in-place roof deck, while relying on a skilled, experienced installer who is knowledgeable enough to avoid oil canning.

#2: Leaking and Water Intrusion Issues

A leaky roof or leaking roof is one of the most frustrating metal roof problems, and from field experience, roof leaks often start quietly before turning into visible water damage. Metal roof leaks are always a possibility, especially when uncontrollable causes combine with human error. Common triggering events include driving rain, heavy snow, melting snow, ice damming, repeated freezing and thawing, strong wind, structural damage, and other weather occurrences. These situations usually lead to extra cost, unplanned roof repair, delays in getting a fixed roof, and risk to valuable items inside the home or building, ultimately affecting home protection and building protection.

In many cases, leaks come down to installer error or installer mistake, which I have personally seen on new installs. Failed fasteners such as screws that are too tight, too loose, or off-center create water entry points at open spots. A failed seam or seam failure along the side rib where roof panels and connected panels meet is often caused by incorrect forming or improper seaming. Another frequent leak source is failed flashing, where flashing material or metal flashing does not stop moisture entry at joints, roof additions, pipes, chimneys, or valleys. On a standing seam metal roof, the flashing area and flashing points are especially sensitive.

Problems also arise when failed sealant or butyl tape in sealing materials break down, allowing water intrusion, dirt, and debris to enter a compromised roof. I have seen leaks caused by damaged sealant, missing sealant, or incorrect application, often linked to inadequate details in contractor details and installation details that ignore manufacturer recommendations and manufacturer details, risking a weather-tight warranty. Early involvement in the installation process, choosing a reputable contractor with quality installs and a good track record, significantly lowers the reduced likelihood of recurring leaks and sudden springing leaks.

#3: Scuffing & Scratching Issues

In many metal roof roofing problems, scuffing and scratching become a common problem once a paint system is applied and the surface is subjected to stress at different point and points of its lifecycle. From my field experience, manufacturers and every manufacturer take precaution to ensure the coil and coils are not scratched during the slitting process, recoiling, or when material is transported to the buyer. Still, during installation, contractors, a contractor, and installers may handle or handles panels and each panel with less care or poor handling, especially during rollforming, where the possibility of being improperly coiled or recoiled exists, causing surface-level damage as sheets rub and get rubbed together and strip the coating along the edge and edges if guards are not used to protect the sheet during shipping by carriers using incorrect lifting devices.

On site, I have seen a machine where components malfunctioned and a coil was inadvertently scraped by a part, while tools or other items were dropped on a panel, or panels were walked on after being installed, leaving areas scuffed in heavy traffic spots near flashing, ladder entries, a common issue with acrylic-coated Galvalume that needs special handling. When you notice a scratch, scuff, or multiple scratches reaching the substrate, bring it to the attention of the manufacturer or contractor; the majority can be fixed with touch-up pen match to the color, but a deep gouge into the core of the steel means the section must be replaced immediately.

#4: Corrosion Risks

Many people choose metal roofing because it defends against corrosion and degradation for decades, often 60+ years, making it the last roof they expect to purchase for their home, homes, building, or buildings. In practice, manufacturers and contractors, including each contractor, effectively help select the right material that can stand up in a specific environment or environments, using protective paint system and systems with coatings and coating layers specifically engineered to resist damage. Still, special circumstances can occur and occurs over the lifetime of roofs, depending on how informed and educated the owner is.

From on-site experience, underside issues appear when a panel is improperly coated, allowing water molecules to get trapped underneath, between the insulation or underlayment, which can cause the metal to weaken if not addressed. I have seen crews use granulated underlayment, install panels right over a shingle roof, and unintentionally scratch the backside, making the system fail from the inside out. This problem can take place quietly until corrosion becomes visible at a later point.

For homes close to the coast, saltwater exposure often means owners don’t qualify for substrate or warranties because of saltwater’s effect. While certain types of metals work better in coastal zones, such as aluminum and zinc, there is no guarantee they will last long without threat. It is critical to make sure you read and analyze the warranty, product specs, and determine your location is not subject to premature failure. Dissimilar metals put together can create negative interaction that causes early damage, while cut edges on a steel standing seam roof may show edge creep, minimal rusting, and occurring flaws. Proper details like folds, hemmed edges that conceal cuts, lap flashing, hemming exposed areas, and a pen for visible touch-ups can minimize appearance issues, because corrosion will happen eventually—whether early, at 50 years, or otherwise is dependent on being different and informed.

#5: Dissimilar Metals & Materials

When combining different metals on a metal roof system, problems often start quietly. I have seen many cases where metal roof material reacts badly once there is direct contact between Galvalume roofing and specific materials like copper, iron, treated lumber, bricks, or concrete. With water acting as an electrolyte, electrons move from the more active material to the less active material, forming an anode and triggering galvanic corrosion. This process leads to staining, early degradation, and long-term corrosion, and over time the metal may even corrode, causing system failure or potential failure. These galvanic reactions are not always visible at first, but they slowly damage the metal roof from the inside out.

From practical site experience, most poor interactions happen where roof parts meet other components. Items such as panels, gutters, fasteners, rivets, flashing materials, lead pipe boots, trim, fascia, and drip edges are often overlooked. Added risks come from nearby siding, wall materials, chimneys, roof-mounted air conditioners, swamp coolers, and copper drain pipes. Even other roofing systems like cedar shake shingles can create hidden issues. This is why a clear discussion with the contractor about all products, metals, and interactions is critical, to ensure everything will react well and avoid costly damage later.

#6: Chalking & Fading

Fading is often the first potential problem homeowners notice on a metal roof, especially when a painted or coated metal panel starts showing color change after long UV exposure from UV rays and the sun, while chalking follows as a whitish residue that becomes clearly visible once the paint resin and pigment on the metal substrate begin their breakdown. From my on-site experience, this issue tends to happen no matter where you live, because every roof is subjected to water, pollution, chemicals, and other substances in the surrounding environment, making these hot topics in roofing discussions. The degree of uneven fading often depend on how evenly the panels are evenly exposed, and while this is familiar to most professionals, reputable manufacturers usually offer paint warranties that cover damage exceeding a specified measurement over a period of time, which should be clearly defined in the warranty.

#7: Noise

Compared to other roofing materials, metal roofs often feel noisier because their harder, more rigid surface tends to reflect sound instead of helping it absorb, which becomes very clear during heavy rain, normal rain, hail, or even raindrops hitting the roof, making the sound feel louder, amplified, and more noticeable inside the building. From my on-site experience, when branches fall, falling debris causes sharp impacts that are easily heard inside, especially if the roof design, type of underlayment, or lack of a proper insulation layer is ignored. Poor detailing allows noise to be transmitted directly through the structure, raising noise levels, while adding solid sheathing beneath the panels can help dampen sound and reduce noise, even though many homeowners overlook how much the right setup can control what is felt and heard daily.

#8: Loose or Missing Fasteners

In metal roofs, fasteners such as screws and nails are meant to stay secured, but over time they can become loose, missing, or dislodged. This usually happens due to expansion and contraction of the metal caused by temperature changes. When this starts, roof problems quietly develop because proper attachment is lost, unwanted movement begins, and the roofing system slowly loses its integrity, turning into a serious maintenance issue I have personally seen worsen when ignored.

- Structural Weakness

- A clear sign of structural weakness appears when loose fasteners or missing fasteners compromise overall structural stability of a metal roof. Once panels are no longer securely attached, they can shift or become dislodged during strong winds and storms, putting the entire roof system at risk of damage, sudden collapse, or long-term failure, which directly threatens building safety.

- Water Infiltration

- Another issue tied to this problem is water infiltration. Small gaps formed by loose fasteners and missing fasteners allow water to penetrate the roof system. From experience, I have seen rainwater and melting snow seep into a building, causing leaks, water damage, mold growth, mildew growth, and hidden interior damage along with deeper structural damage due to trapped moisture, especially when left long term and not addressed promptly.

- Increased Vulnerability to Wind Uplift

- There is also increased vulnerability to wind uplift when properly secured fasteners can no longer resist uplift forces. Under strong winds, loose fasteners and missing fasteners make panels more susceptible to partial roof detachment or even complete roof detachment, leading to further damage to the building as intense pressure forces trigger full roofing failure.

- Increased Maintenance and Repair Costs

- Finally, this problem results in increased maintenance and rising repair costs. Loose fasteners and missing fasteners demand immediate attention and timely repair, because ignoring issue scenarios often lead to extensive damage. In the long run, increased costs are unavoidable without regular inspections, prompt replacement, protection of roof integrity, and a focus on minimizing damage through proper upkeep and smart maintenance planning.

#9: Poor Insulation and Energy Efficiency

A metal roof often struggles when poor insulation or insufficient insulation is part of the roof system, directly affecting energy efficiency inside the building interior, interior space, and indoor building space. Because metal is a highly conductive metal, it allows heat transfer and cold transfer, turning the roof into a conduit for heat influenced by outside temperature. In hot weather, metal roofs absorb heat, retain heat, and increase heat gain, which results in significant energy loss, higher energy consumption, increased cooling demands, increased heating demands, rising utility bills, reduced comfort, and uncomfortable occupants, especially when temperature imbalances create too hot areas and too cold areas instead of comfortable temperatures and a comfortable indoor environment.

From hands-on experience during the construction phase and later retrofitting process, I have seen how proper insulation such as reflective barriers and foam insulation acts as crucial prevention against wasted energy while supporting a consistent indoor climate. Without these steps, metal roofs can be less energy-efficient than other roofing materials, even when the right design is intended, because missing performance features leads to additional cooling energy use and ongoing strain on the building.

Modern solutions focus on energy-efficient features that deliver enhanced energy performance, including reflective coatings, durable roof finishes, and reduced solar heat gain through smart surface choices. When paired with ventilation systems, proper airflow facilitation, and effective heat dissipation, along with cool roof designs that maximize reflected sunlight and support emitted heat reduction, these energy-efficient measures help achieve reduced energy consumption, lower utility costs, and an environmentally friendly design without sacrificing long-term comfort.

#10: Denting and Surface Damage

A metal roof can face serious denting issues, especially when metal roofs are exposed to impact from hail, hailstones, and falling debris. The level of damage often depends on metal thickness, overall thickness, and the type of metal or metal type used. In my field experience, aluminum and aluminum roofs, being softer metals, are more prone to dents than steel, steel roofs, and other harder metals. Even a small dent can lead to the visible formation of dents, including deeper dents or extensive dents, which affect the roof surface, roof appearance, and overall aesthetic appearance of a dented metal roof, increasing long-term susceptibility to wear.

In commercial and industrial facilities, daily foot traffic, machinery, equipment, and personnel working on the roof during installation or routine maintenance and maintenance activities can also contribute to impact damage. Poor installation techniques, especially improper installation techniques, combined with weak roof support or insufficient roof support, and extreme temperature fluctuations, are various reasons dents develop over time. While denting may not always reduce roof functionality, repeated damage can eventually potentially require repairs, particularly when stress points form under repeated impacts.

FAQs:

What causes a metal roof to fail?

From years of site inspections, I have seen that metal often breathes because of fluctuations in temperature, which makes panels expand in heat and contract during colder weather. When fasteners are not installed properly, this constant expansion and contraction can slowly loosen metal roof panels and cause hidden damage over time, turning a strong system into a failing one even when the surface still looks fine.

Why does my metal roof leak in heavy rain?

From my on-site experience, one common cause of leaks in heavy rainfall and storms is poor installation, as mentioned earlier in many inspections I have handled. When gaps form due to inadequate sealing around flashings or improperly fastened panels, water seep through the system, leading to leaks that homeowners often notice only during severe weather. Another potential cause behind persistent metal roof leaks is physical damage and long-term deterioration, which slowly weaken the roof’s ability to resist water pressure during heavy rain.

What is the best way to fix a leaking metal roof?

- Start by finding the leak and sealing it yourself with sealant or tape; this often stops small water entry points fast.

- If leaks spread, applying a complete elastomeric roof coating helps seal the surface and handle rain better.

- For hidden moisture paths, applying spray foam on the roof improves sealing and adds insulation to the metal system.

- When repairs fail, metal roof retrofitting corrects design flaws without removing the entire roof.

- As a last option, a complete replacement solves long-term leakage when damage is extensive.

Do metal roofs need maintenance?

For me, regular checks on a metal roof are a critical part of maintenance because they help in preserving and protecting the long-term investment, allowing the roof to continues to look good and perform well; this routine also ensures you save both time and money by not having to spend on costly repairs in the future, which many homeowners overlook until issues appear.